The new World Robotics Report by the IFR International Federation of Robotics showed an all-time high of up to 520,000 new industrial robots installed in 2021 in factories around the world, which represents a growth rate of 31% year-on-year. The demand for automated transportation of goods in intralogistics made a significant contributed to this strong growth.

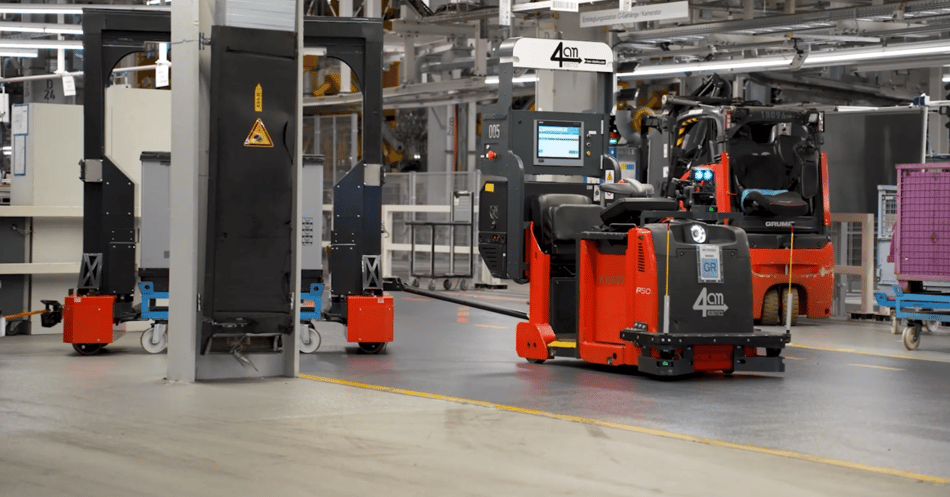

Autonomous mobile robots (AMR) are able to pick, transport, and sort items in manufacturing and distribution facilities without the need for manual intervention – they are the key to unlocking the enormous potential of the integrated smart factory, ensuring that logistics and production processes are connected. AMRs are in high demand as they have a vast array of benefits, such as being able to prevent product damage, reduce labor costs, enhance productivity, and automate processes. Major players in several industries and verticals, including automotive, transportation, and food & beverages, are already reaping the rich rewards of adopting AMRs.

But where is it heading? What are the AMR trends and current challenges for the next big step in Mobile Robotics? We asked our AMR experts from 4am Robotics who have been developing our heterogenous AMR fleet since 2016 to give you insights.

1. Sensors

Can autonomous mobile robots see where they are going? Sensor technology is essential for ensuring they move in the right direction!

An autonomous system needs to gather information on its environment. This is why our tugger trains, forklifts and mobile cobots are fitted with multi-sensor systems.

Some examples of common sensors are:- Ultrasonic sensors for active ranging

- Lidar sensors for detection and localization

- GPS sensors for localization

- Camera technology for object detection

- Gyroscopes for better guidance

…and many more!

But how can it filter this enormous amount of information? This is where smart sensor software comes in! With sophisticated algorithms and AI, AMRs are getting better and better at interpreting stimuli and generating meaningful information that the system can act upon.

2. Localization

How do autonomous mobile robots know where they are? GPS technology isn’t sufficient for precise positioning: It only ensures accuracy within several meters and the signal is weakened by factory walls.

So how do AMRs actually do it?

The answer to this is localization. Research on localizing mobile robots in industrial environments has been thriving over the last few years. Now there are several solutions available for AMRs to determine their positions.

One of them is the creation of a virtual map and localization through contour-based navigation. 🗺️📍

Developers create a detailed map of the site. While the robots drive through the factories, laser sensors constantly check their positions on this map🎆

But what happens when you want to move things around? How can several AMRs fleets interact on a single map?

3. Autonomous navigation

Imagine you are a mobile robot driving in industrial environments! 🤖

Can you come up with all the navigation challenges?

Autonomous mobile robots need to plan their routes and react to unforeseen events!

They must be able to:- avoid obstacles

- pass through narrow corridors

- optimize traffic flow

- use distance control when situations are unclear

- dock to their stations

To allow them to find their way around properly, AMRs need to gather knowledge about their environment and then be able to make smart decisions! Can you help them make better ones?

4. Traffic management

robot meets obstacle ➡️ stop or avoid ❌

robot meets person ➡️ stop or avoid❌

robot meets robot ➡️ “Who goes first?”🤔❓

To find an answer to this question, autonomous mobile robots need to be connected with each other.

Whenever autonomous systems drive in industrial environments, traffic needs to be actively managed.

Traffic management control (TMC) determines which rules take effect at decision points in the traffic flow.

There are two ways to approach TMC:

- In centralized traffic management, a central system makes the decision for the vehicles (e.g. a master control system.)

- In decentralized traffic management, AMRs communicate with decentralized systems at decision points to obtain clearance. (e.g. PLC)

5. Handling objects

Let’s improve manipulation! 😈

In robotics, a manipulator is a device that enables physical interaction with the environment. It typically consists of a series of joints and an end effector or gripper.

Manipulators are often designed to mimic the human workspace, allowing them to take over similar tasks such as grasping and moving objects. 💪🦾

However, this can only be done to a certain extent, most often restricted to standardized boxes or containers. Handling objects which differ in size, weight, shape and surface structure require highly dexterous workspaces and specialized grippers. Kinematical analysis and end effector design are crucial here for ensuring successful manipulation.

4am Robotics is currently developing grippers for loading and unloading…

- Assembly racks

- Tugger train trailers

- Roller conveyors

6. Environmental influences

Can autonomous mobile robots drive in the rain? ☔ Why not?

Environmental influences pose numerous challenges for autonomous systems. When sensors and lasers are covered by rain, snow or dust, AMRs literally go blind. 👀 ❓

Also, robots might confuse the rain with obstacles.

How can sensors tell the difference between heavy rain and a wall? Developers need to improve image recognition and make sure AMRs can understand the patterns of rain and snow!

To prevent scanners from becoming dirty, 4am Robotics has developed a scanner cleaning system that ensures visibility.

7. Capacity management

🚨Warning: battery low ⚡

Heterogenous AMR fleets pose huge challenges for capacity management.

Autonomous tugger trains, forklifts and cobots need to blend seamlessly into day-to-day operations in smart factories. One massive advantage of AMRs is that they are very flexible.

But when is the right time to recharge?

How many docking stations are needed?

How can we deal with the fact that tugger trains can move much faster than forklifts?

Smart systems are needed to monitor and manage the utilization rate of autonomous mobile robots!

More research is needed to develop AMRs even further.